Locomotive & railcar maintenance planning

Optimize maintenance activities including shop assignment and utilization

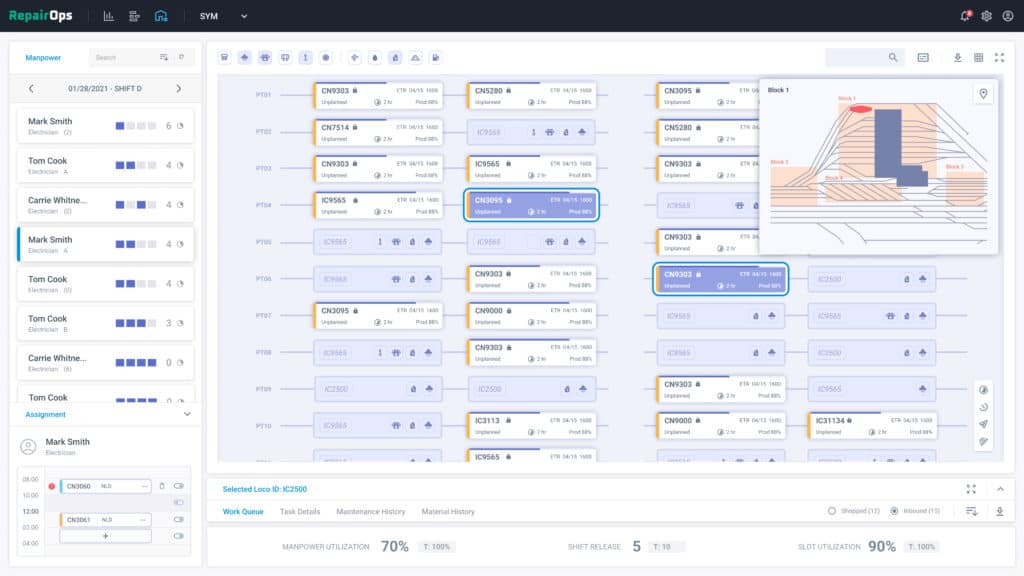

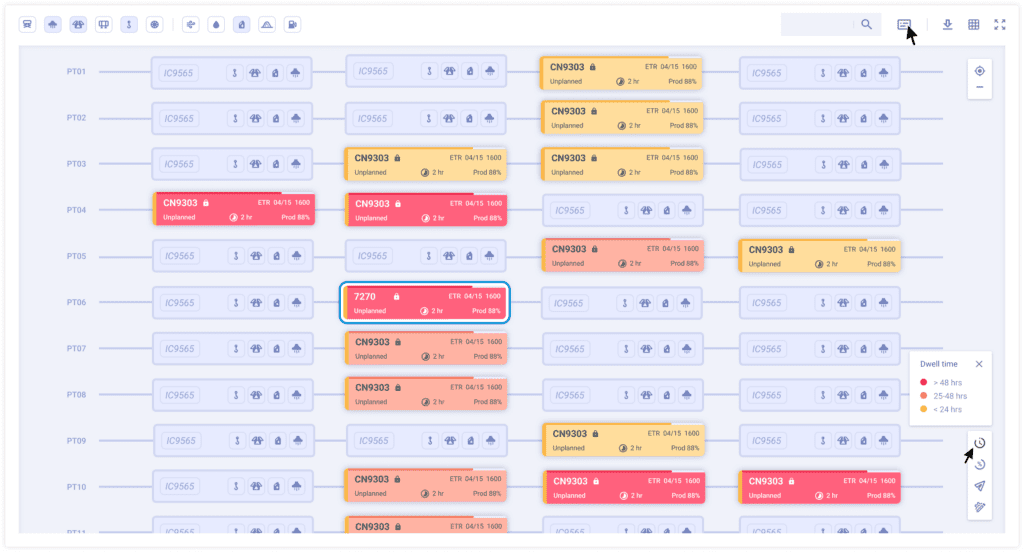

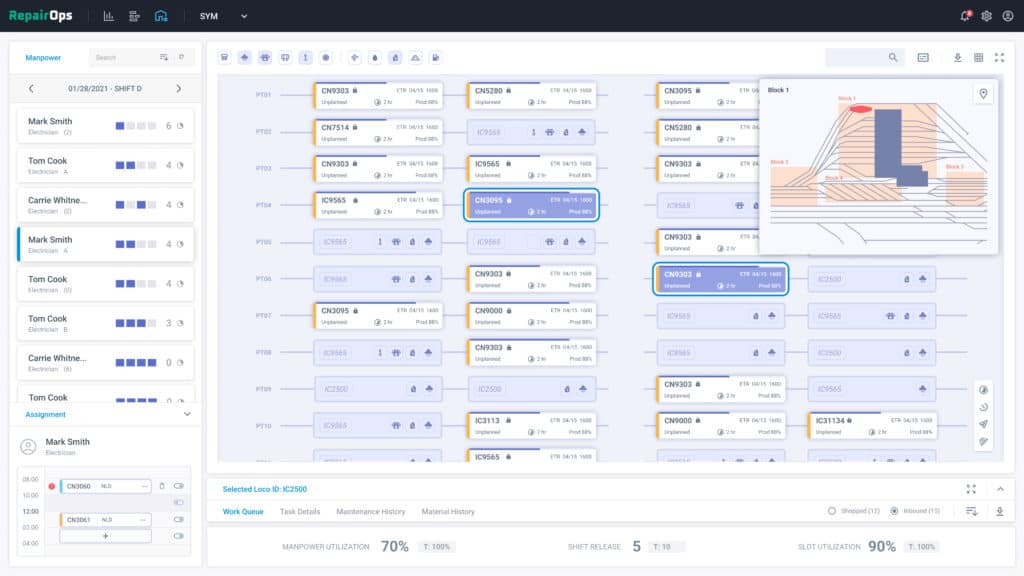

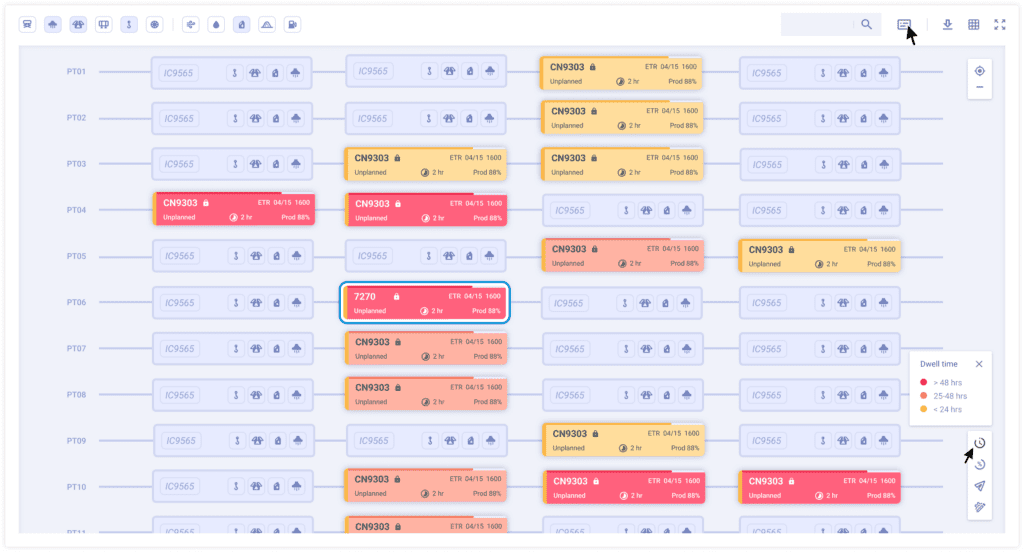

Smarter shop scheduling

Plan, monitor, and optimize asset shop assignments manually or automatically. Increase productivity and reduce downtime.

Easily configured for short and long-term planners, shop managers, maintenance control centers, leadership, and more

What-if analysis to plan for a variety of heavy maintenance scenarios

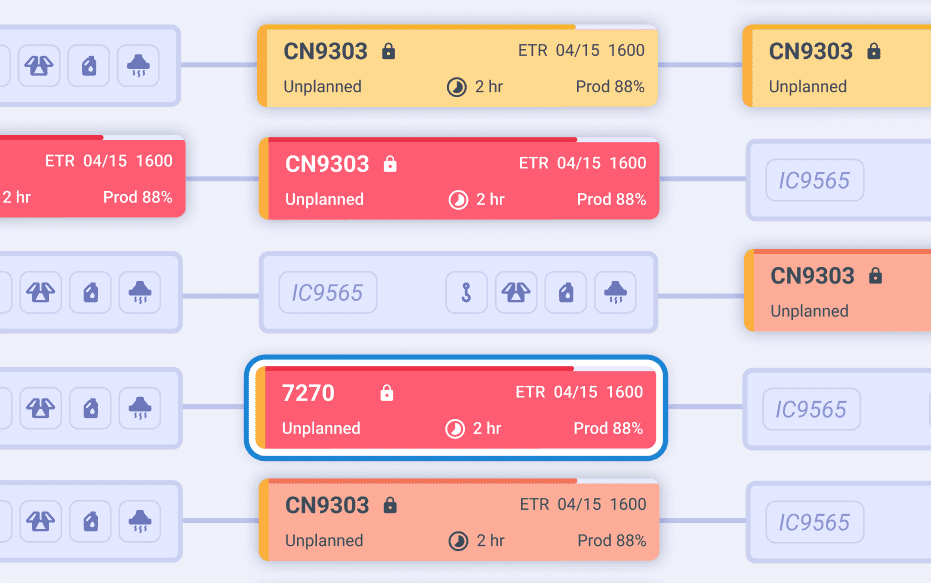

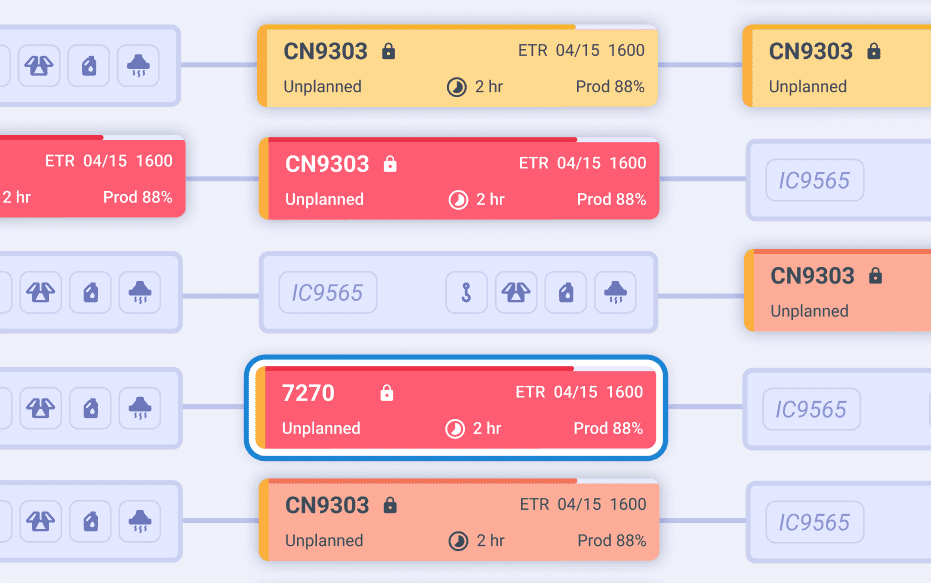

Keep maintenance under control

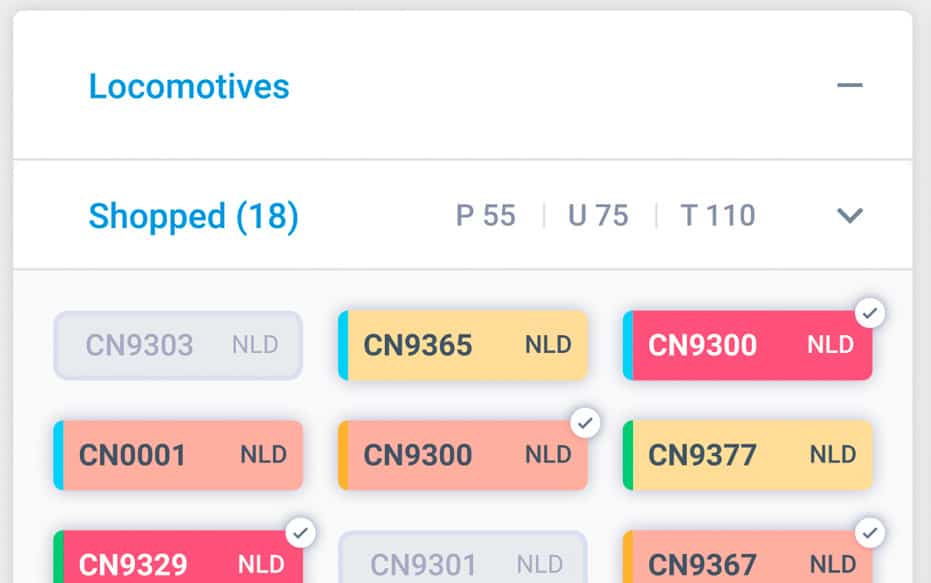

Enable asset management in shops in real-time to view progress and assignments. Balance shop capacity, workload, and capabilities with inspection and maintenance priorities.

Address a wide range of variables and constraints including shop capacities & capabilities and demand for maintenance.

Create heavy maintenance plans 1-3 years ahead of time.

Measure success with KPIs

Keep an eye on the metrics that matter to you. Compare projections to real-time results to make sure everything’s on track.

Rich reporting capabilities covering executive dashboards, pivot reports, and pre-formatted reports

Provides heat map and decision support for managing exceptions and critical issues

Smarter shop scheduling

Plan, monitor, and optimize asset shop assignments manually or automatically. Increase productivity and reduce downtime.

Easily configured for short and long-term planners, shop managers, maintenance control centers, leadership, and more

What-if analysis to plan for a variety of heavy maintenance scenarios

Keep maintenance under control

Enable asset management in shops in real-time to view progress and assignments. Balance shop capacity, workload, and capabilities with inspection and maintenance priorities.

Address a wide range of variables and constraints including shop capacities & capabilities and demand for maintenance.

Create heavy maintenance plans 1-3 years ahead of time.

Measure success with KPIs

Keep an eye on the metrics that matter to you. Compare projections to real-time results to make sure everything’s on track.

Rich reporting capabilities covering executive dashboards, pivot reports, and pre-formatted reports

Provides heat map and decision support for managing exceptions and critical issues

Advanced optimization algorithms help you:

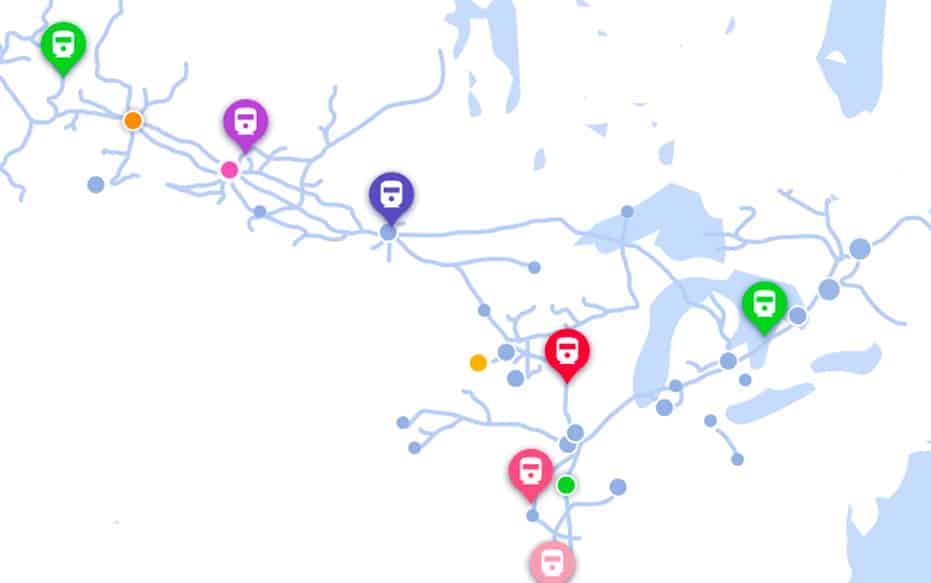

Create detailed train and maintenance plans for periods ranging from days to months to years.

Support all rail operations, including mining, freight, passenger, or any combination of these.

Automatically resolve conflicts in line with business goals.

Create multiple scenarios and compare KPIs to find the best plan.

Stay informed

Sign up now to stay informed of latest industry news and product updates.

Increase productivity and reduce downtime

Reduce maintenance costs through improved shop efficiency.

Increase fleet availability through better planning and usage.

Operate the same number of trains with fewer assets.

What-if analysis

Test for a variety of heavy maintenance scenarios with simulations.

Maintenance optimization

Task assignment based on real-time tracking of inbound asset locations.

Heavy maintenance planning

Plan years ahead with given slots in internal and external shops.

Interactive maintenance planning

Recommend running and heavy maintenance plan on the interactive user interface

Asset shop assignment

Consider shop capacities, workloads, and maintenance demand while assigning.

Seamless integrations

Connect with your existing solutions.