Rail scheduling & maintenance optimization

Enhance your network with rail's best optimization solutions

Increase asset utilization, service quality, and profitability while staying environmentally friendly.

Empowering

the

biggest names

in rail and mining

Unlock the hidden potential

in your rail operations

We have combined deep industry knowledge with artificial intelligence (AI) to solve some of the biggest challenges facing freight and transit rail providers today.

Optimization solutions solving

rail’s unique challenges

Value at each step

Visibility

See your network operations in real time.

Decision support

Direct decision makers to better choices.

Optimization

Automate decision-making.

Value at each step

Visibility

See your network operations in real time.

Decision support

Direct decision makers to better choices.

Optimization

Automate decision-making.

Create train schedules and plan maintenance

- Increase rail network capacity.

- Reduce train dwell time.

- Improve schedule adherence.

- Focus on proactive planning.

Improve locomotive utilization with optimized train assignments

- Assign locomotives based on horsepower or tractive effort.

- Plan for the future with the help of an interactive train graph.

- Recover faster from disruptions.

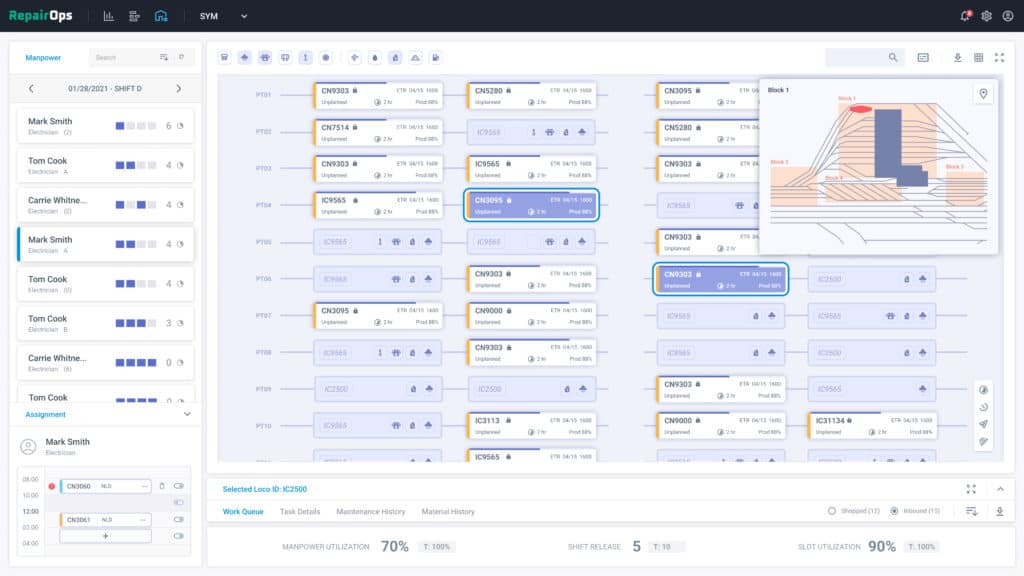

Simplify maintenance activities with the help of decision support and optimization

- Maximize asset utilization.

- Reduce dwell time.

- Improve shop productivity.

$

0

M+

Savings for our customers through optimization

0

%

of Class I railroads served

0

+

Years of serving the rail industry

Selected case studies

BNSF increases operational efficiency

Optym helped BNSF with its rail maintenance optimization.

-

Increased profits by 3% through efficiency gains

-

Increased life of trains

-

Reduced downtime

CSX locomotive operating plan optimization

Optym developed a locomotive optimization software solution to regularly optimize operating plans of over 4,000 locomotives with different pulling capabilities.

-

Reduced locomotive operating costs by 3-5%

-

Determined the optimal fleet size and mix

-

Enabled capital investment studies

Norfolk Southern railroad blocking optimizer

Optym helped integrate its blocking optimizer with Norfolk Southern’s in-house simulation system.

-

Cut blocking plan time from weeks or months to a matter of days

-

Adapted blocking plans as shipment volumes changed

-

Gained ability to redirect traffic in the event of disruptions